Maximizing Machinery Protection with the Bently Nevada 3300XL 5/8mm Proximitor Sensor

December 30,2024

Maximizing Machinery Protection with the Bently Nevada 3300XL 5/8mm Proximitor Sensor

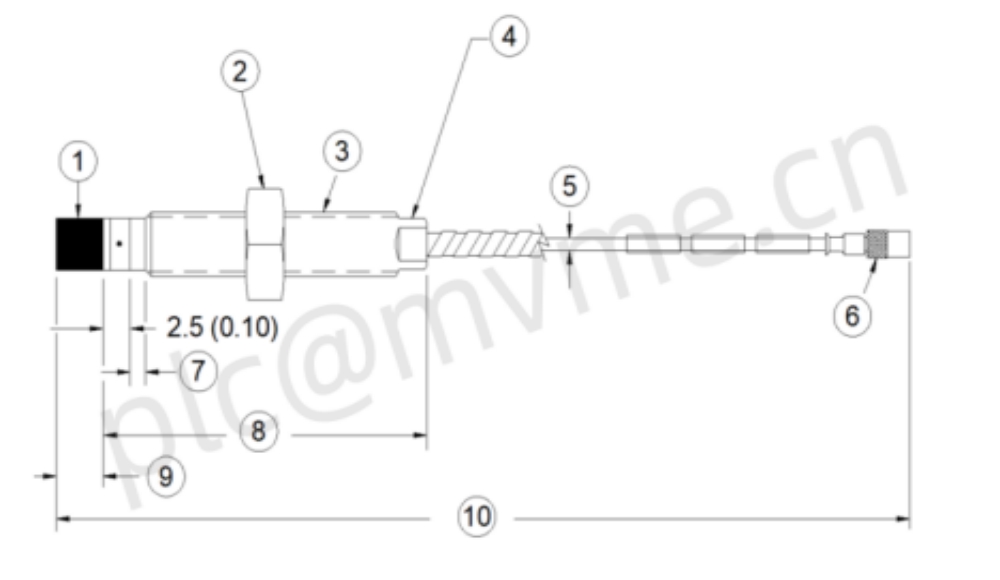

The Bently Nevada 3300XL 5/8mm Proximitor Sensor is part of the 3300XL Series of proximity sensors designed for high-performance vibration and position monitoring applications. The 3300XL series is well-known for its reliability and precision in critical industrial environments, particularly in machinery protection systems.

Key Features of the 3300XL 5/8mm Proximitor Sensor:

High Accuracy and Precision: The 3300XL 5/8mm Proximitor provides high-precision measurements of the displacement between a machine component (such as a shaft or bearing) and the sensor, with an accuracy of 5/8mm. It is ideal for monitoring radial or axial displacement of rotating equipment.

Advanced Sensing Technology: Utilizing eddy-current technology, the 3300XL proximitor sensor accurately measures the gap between the sensor probe and the target (usually a rotating machine part). It converts the physical displacement into an electrical signal, which is then processed for analysis.

Robust and Durable Design: Designed to operate in harsh industrial environments, the 3300XL sensor is highly resistant to extreme temperatures, electromagnetic interference (EMI), vibration, and shock. It is commonly used in power plants, oil and gas refineries, and heavy manufacturing industries.

Easy Integration: The 3300XL sensor is designed for seamless integration with Bently Nevada 3300/01 and 3500 series monitoring systems. It is compatible with various vibration and proximity monitoring systems, making it a versatile choice for many industrial applications.

Wide Measurement Range: The sensor is capable of measuring large displacement variations, typically in the range of 0 to 5/8mm. This range is suitable for most rotating machinery monitoring systems, offering both fine and coarse measurements depending on the application.

Low Power Consumption: The 3300XL proximitor operates with low power requirements, making it energy efficient and ideal for use in systems where power consumption is a consideration.

Enhanced Diagnostic Capability: The sensor supports advanced diagnostic features that help identify potential issues such as misalignment, imbalance, and bearing wear, reducing the risk of failure and minimizing downtime.

Applications:

Turbines and Compressors: Used in gas and steam turbines, as well as compressors, to monitor shaft displacement and alignment.

Motors and Pumps: Ideal for monitoring motor shafts, pump rotors, and other rotating machinery where precise alignment and vibration monitoring are critical.

Generators and Wind Turbines: Used in power generation plants, including both conventional and renewable energy sources, to ensure equipment operates within safe tolerances.

Bearings and Bearings Housing: The sensor can be used to detect wear or misalignment in bearings and housing in machinery.

Conclusion:

The Bently Nevada 3300XL 5/8mm Proximitor Sensor offers exceptional accuracy, reliability, and durability for monitoring displacement and vibration in rotating machinery. With its robust design, advanced sensing technology, and ease of integration with Bently Nevada monitoring systems, it provides invaluable data for machinery protection and performance optimization in demanding industrial applications.

Network Supported

Network Supported