Enhancing Industrial Operations with the Bently Nevada 3500 Monitoring System

December 20,2024

Enhancing Industrial Operations with the Bently Nevada 3500 Monitoring System

In today's fast-paced industrial landscape, ensuring the reliability and safety of machinery is paramount. The Bently Nevada 3500 Monitoring System, a flagship offering from Baker Hughes, has emerged as a trusted solution for machinery protection and condition monitoring. With its advanced features, modular design, and industry-wide applicability, the 3500 series sets the benchmark for monitoring critical assets. This blog explores the capabilities, benefits, and transformative impact of the Bently Nevada 3500 Monitoring System.

A Brief Overview of the Bently Nevada 3500 Series

The Bently Nevada 3500 series is designed to provide real-time monitoring, early anomaly detection, and machinery protection. It integrates seamlessly into various industrial environments, offering unparalleled reliability and precision. Industries such as oil and gas, power generation, manufacturing, and chemical processing rely on this system to safeguard their critical assets and maintain operational continuity.

Key Features of the 3500 Monitoring System

The Bently Nevada 3500 series is known for its comprehensive feature set that addresses the needs of modern industries:

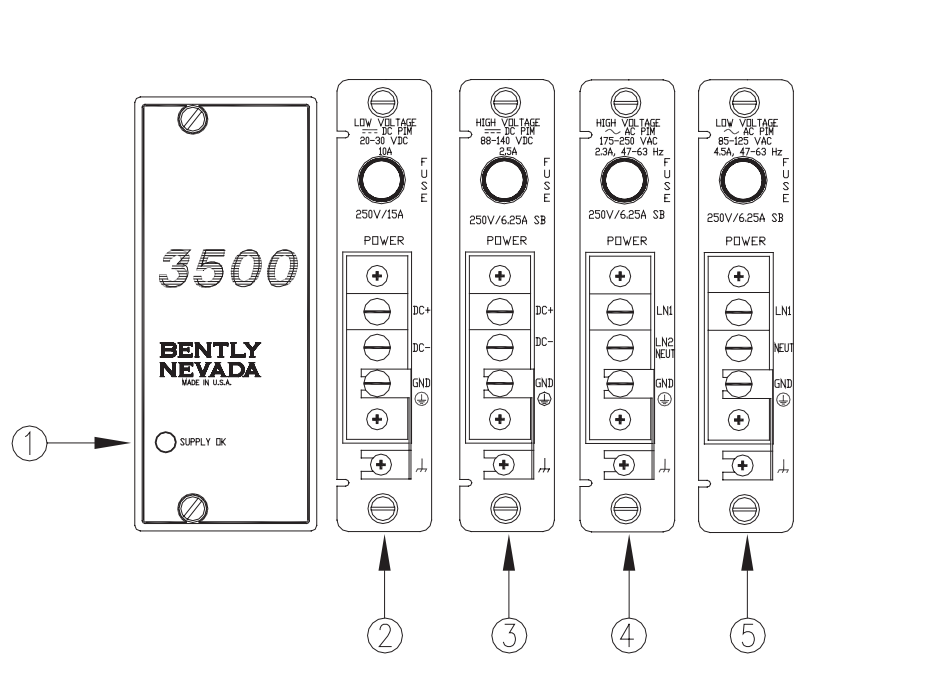

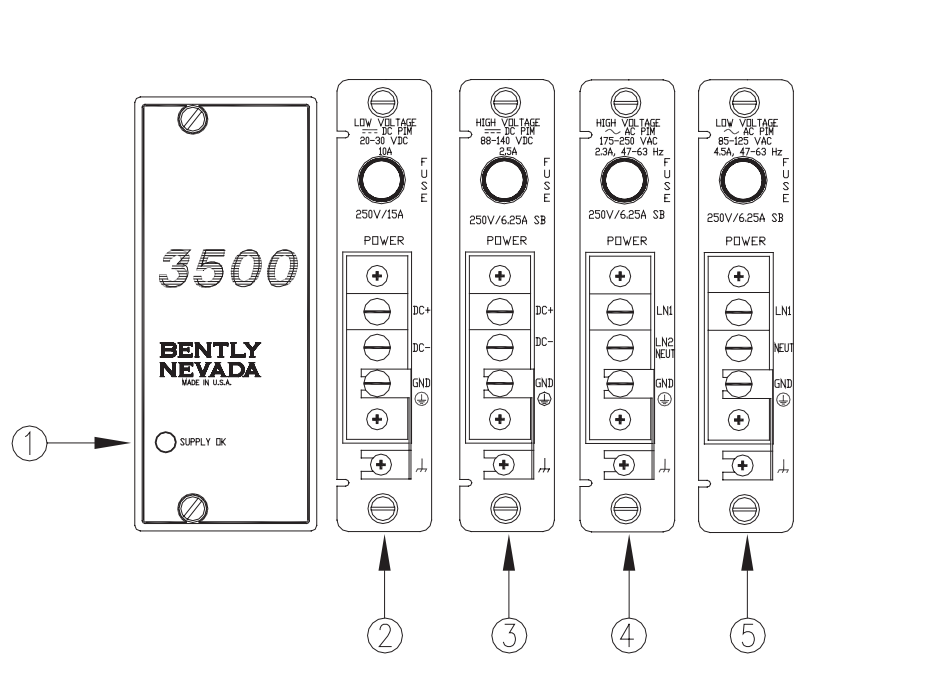

Modular Architecture:

The 3500 system's modular design allows for easy customization and scalability. Users can select and integrate only the modules required for their specific applications, reducing costs and optimizing performance.

Real-Time Data Acquisition:

The system collects real-time data on various machinery parameters, including vibration, temperature, and speed. This data is critical for identifying potential issues before they escalate into costly failures.

Advanced Diagnostics:

Equipped with advanced diagnostics capabilities, the 3500 system enables in-depth analysis of machinery health. It can detect and diagnose issues such as unbalance, misalignment, and bearing wear.

Robust Display Options:

The Bently Nevada 3500/93 Back-lighted Display provides operators with a clear and intuitive interface for accessing critical data. The backlit screen ensures visibility in all lighting conditions, enhancing usability.

Integration with Control Systems:

The 3500 series integrates seamlessly with Distributed Control Systems (DCS) and Supervisory Control and Data Acquisition (SCADA) systems, allowing operators to centralize monitoring and control.

Comprehensive Alarming and Notifications:

The system features a robust alarm management mechanism, alerting operators to deviations in machinery performance and enabling prompt action to mitigate risks.

Applications Across Industries

The versatility of the Bently Nevada 3500 Monitoring System makes it indispensable across various industries:

Oil and Gas:

Monitors compressors, pumps, and turbines in upstream, midstream, and downstream operations, ensuring uninterrupted production.

Power Generation:

Protects critical assets such as generators and steam turbines, enhancing operational reliability and efficiency.

Manufacturing:

Safeguards rotating machinery, enabling smooth operation of production lines and reducing unplanned downtime.

Chemical Processing:

Monitors reactors, mixers, and other critical equipment to maintain process integrity and safety.

Conclusion

The Bently Nevada 3500 Monitoring System represents the pinnacle of industrial monitoring technology. With its robust features, versatile applications, and proven benefits, it empowers industries to achieve higher levels of safety, efficiency, and profitability. For organizations striving to maintain a competitive edge in today’s dynamic industrial landscape, the 3500 series is not just a tool—it’s a strategic asset.

Network Supported

Network Supported